Home

>

News

>

Media Focus

> Boosting Your Automotive Production Line? Discover SBT Ultrasonic's High-Efficiency Welding Solutions

As automotive manufacturing processes advance, ultrasonic welding technology is rapidly expanding from interior to exterior applications, driving transformative changes in the industry. This technology not only overcomes the limitations of traditional welding methods but also provides reliable support for vehicle lightweighting and overall quality enhancement.

Ultrasonic welding utilizes high-frequency mechanical vibrations to generate frictional heat at the molecular level of plastic components, achieving instantaneous melting and molecular fusion. This process offers multiple advantages:

No adhesives required, eliminating VOC (Volatile Organic Compounds) emissions entirely.

Welding times typically range from 0.1 to 3 seconds, significantly boosting production efficiency.

Weld strength approaches that of the base material, ensuring joint reliability.

These benefits enable automakers to achieve both economic and environmental gains.

1) Exterior Applications

In headlight manufacturing, ultrasonic welding demonstrates exceptional advantages, particularly in lens sealing. Compared to traditional hot plate or vibration welding, ultrasonic welding minimizes the heat-affected zone through localized melting, preventing lens fogging, yellowing, or optical distortion caused by overheating. This preserves lens clarity and optical performance. Simultaneously, the technology forms uniform and dense welds rapidly, ensuring structural integrity, excellent airtightness, and watertightness—enhancing the reliability and lifespan of headlight assemblies.

SBT Ultrasonic has successfully applied its advanced ultrasonic plastic welding technology to various headlight products, including license plate lights, fog lights, DRLs, and high-mounted stop lights. For different headlight types, SBT's equipment precisely controls welding parameters (e.g., amplitude, pressure, time, and energy) to adapt to diverse material combinations and structural designs, ensuring strict waterproofing, dust resistance, and mechanical performance standards.

2) Interior Applications

In automotive interior manufacturing, ultrasonic welding is widely used for bonding parcel shelves and acoustic insulation components. This eliminates the need for mechanical fasteners or adhesives, reducing weight while avoiding stress concentration or VOC emissions associated with conventional methods.

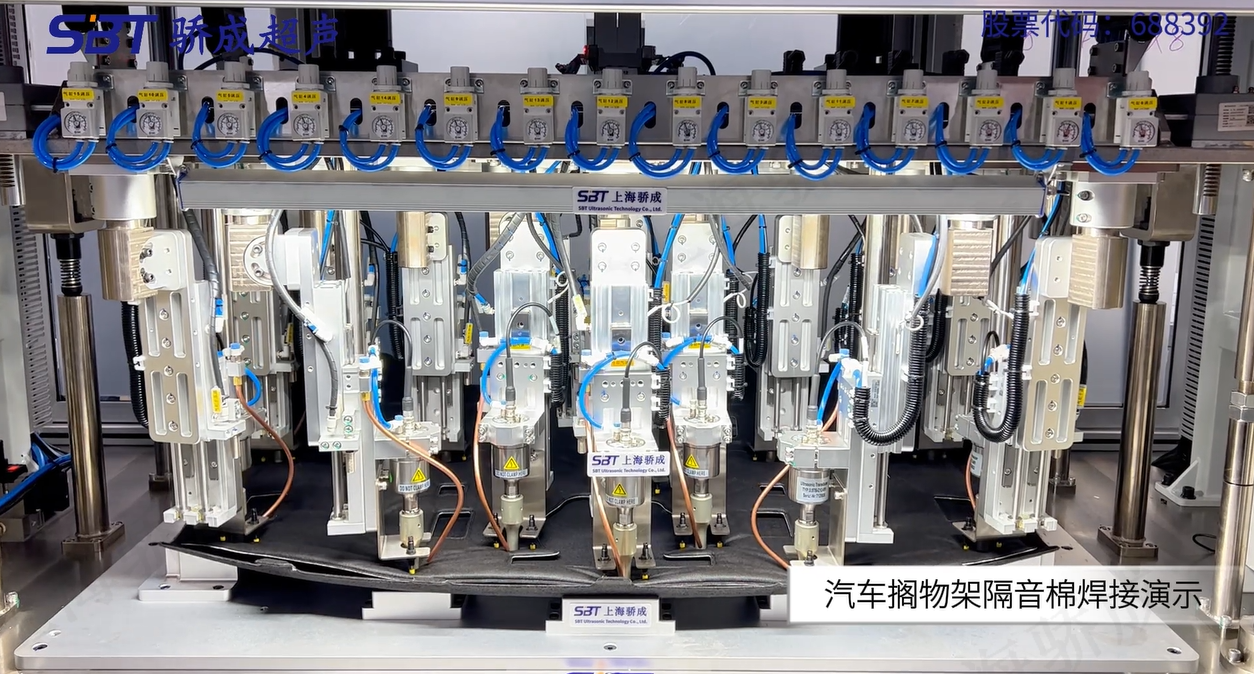

Ultrasonic Welding of Automotive Parcel Shelf Acoustic Insulation

For parcel shelf welding, ultrasonic technology creates molecular-level fusion bonds without compromising surface aesthetics. The weld strength matches the base material, ensuring structural integrity under dynamic loads during vehicle operation.

In acoustic insulation welding, ultrasonic technology excels at bonding multilayer composite materials. High-frequency vibrations rapidly fuse surface fibers with substrates, forming uniform weld interfaces that maintain porous sound-absorbing properties while ensuring layer adhesion.

SBT Ultrasonic's self-developed adaptive welding system intelligently optimizes parameters based on material properties, thickness variations, and structural characteristics of parcel shelves and acoustic insulation. This ensures stable, reliable welds meeting stringent automotive durability and NVH requirements. The technology is already deployed across multiple vehicle models from major OEMs, supporting lightweighting, sustainability, and high-quality manufacturing.

With the rapid development of new energy vehicles (NEVs) and smart connected cars, demands for lightweighting and advanced manufacturing processes are increasing. Ultrasonic welding is playing an increasingly critical role in joining composite materials—from structural to functional components, and from conventional to NEVs—offering unique advantages and comprehensive upgrade opportunities.

SBT Ultrasonic's ultrasonic plastic welding machines integrate with MES and quality monitoring systems, enabling real-time process monitoring and automatic parameter adjustments based on material properties. This ensures consistent weld quality. Additionally, customized horn designs accommodate complex automotive part geometries.

Looking ahead, SBT will deepen innovation in intelligent welding systems, leveraging AI to achieve autonomous process optimization and predictive maintenance. The company will also accelerate R&D in new materials and processes, providing ongoing technical support for industry advancement.