Home

>

News

>

Exhibition Info

> SBT Ultrasonic's New-Generation Ultrasonic Thermosonic Die Bonder Debuts at CSEAC 2025!

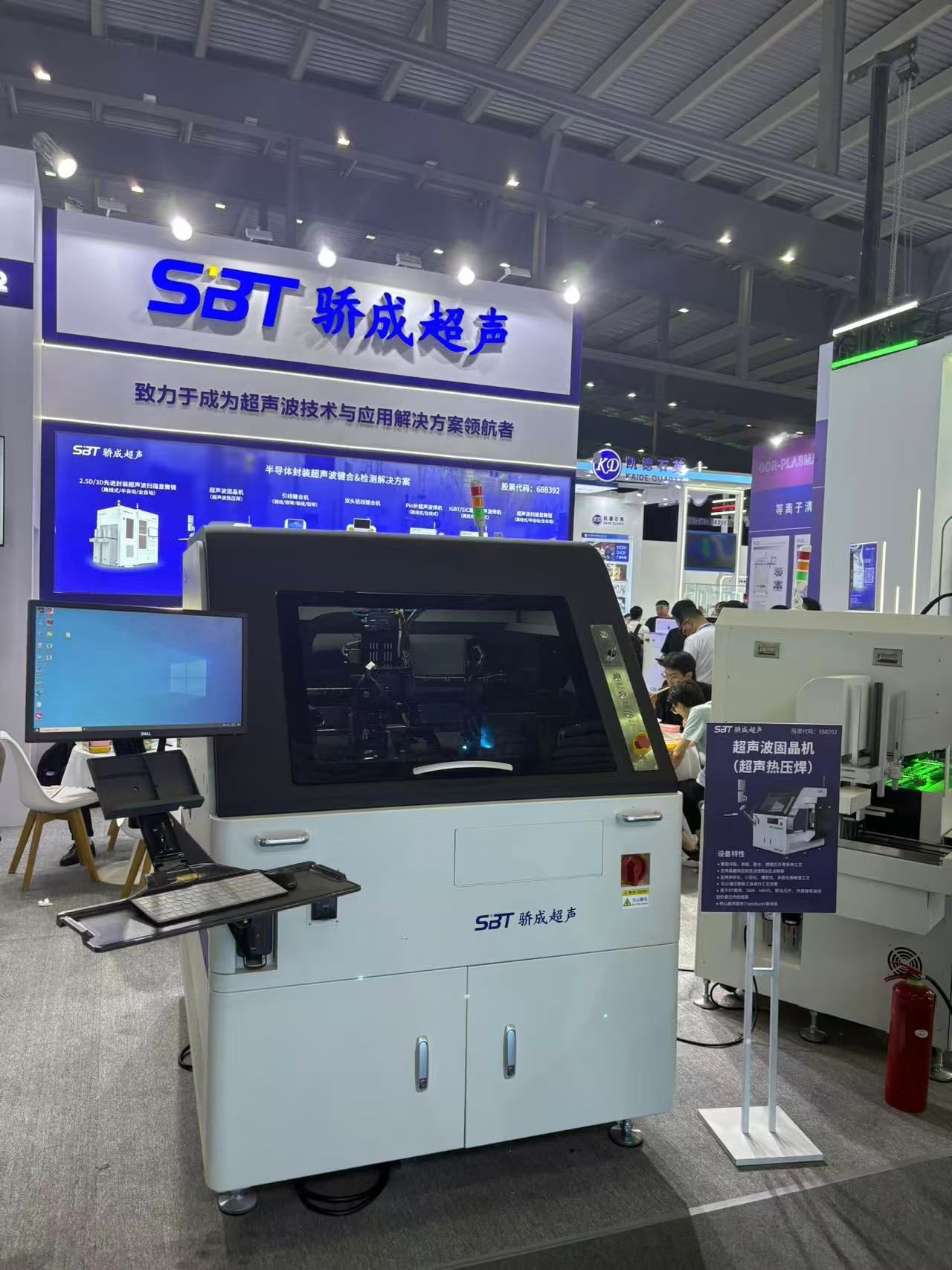

Recently, the 13th Semiconductor Equipment and Core Components & Materials Exhibition (CSEAC 2025) opened in Wuxi under the theme "Strengthening China's Chip Industry, Embracing the Core World". The event showcased the latest advancements in semiconductor critical equipment, core components, and key materials, attracting experts and industry leaders from 22 countries and regions.

SBT Ultrasonic Technology Co., Ltd. (SBT Ultrasonic, Stock Code: 688392), a leading listed enterprise in semiconductor ultrasonic equipment, unveiled its new-generation Ultrasonic Thermosonic Die Bonder and other cutting-edge solutions, highlighting its technical prowess in semiconductor packaging equipment.

As advanced packaging technologies like Chiplet and 3D IC become core paths to break through the bottlenecks of Moore's Law, precision packaging is now critical to determining chip performance and reliability.

SBT Ultrasonic's new-generation Ultrasonic Thermosonic Die Bonder offers a high-precision, high-efficiency, and highly flexible localized chip mounting solution for back-end semiconductor packaging and testing processes.

1 Ultra-High Precision

Achieves sub-micron precision in die placement via multi-vision guidance systems.

Supports diverse processes: epoxy dispensing, eutectic bonding, solder paste, nano-silver sintering, gold-gold bump bonding, etc.

Compatible with advanced techniques like flip-chip, TCB thermocompression bonding, and ultrasonic welding.

Applicable to third-generation semiconductor chips (e.g., GaN, SiC), photonics, 5G RF, high-power IGBT, MEMS, LiDAR, and IC advanced packaging.

2 Innovative Ultrasonic Bonding

Utilizes 20–200 kHz high-frequency ultrasonic vibrations to generate localized heat at chip-substrate interfaces, removing oxides and enabling atomic-level diffusion.

Forms solid-state bonds with minimal preheating (chip: ~200°C; substrate: ~100°C), reducing thermal damage risks and energy consumption while boosting UPH and reliability.

3 High Flexibility & Modularity

Adapts to various feeding methods: 6″/8″/12″ wafers, waffle/gel boxes, tape feeders.

Supports diverse process modules: dispensing/eutectic bonding/flip-chip.

Features multi-station intelligent horn systems enabling zero-downtime production switching.

Integrates programmable vision lighting and high-precision motion control for complex multi-component production.

4 Full-Chain Independent R&D

Backed by Shanghai Jiao Tong University's technical team, SBT Ultrasonic has built a fully independent R&D system from core algorithms to key components.

Holds 400+ intellectual property rights and self-develops critical parts like ultrasonic generators and transducers.

Collaborates with top universities (Tsinghua, Peking University, etc.) to translate research into industrial applications, breakthroughs in multi-physics field control (ultrasonic-thermal-pressure), and material interface behavior regulation.

While the global high-end ultrasonic welding equipment market is dominated by international players (e.g., Branson, Herrmann, Dukane), SBT Ultrasonic is advancing the localization of high-end ultrasonic plastic/nonwoven welding systems. Its equipment rivals imported alternatives in precision (±0.02mm) and stability (CPK ≥1.67) while excelling in energy efficiency.

With ultra-high precision, reliability, and flexible design, SBT Ultrasonic's Thermosonic Die Bonder builds a significant technical advantage in the semiconductor packaging industrial chain. As 5G, AI, EVs, and IoT rapidly develop, SBT Ultrasonic continues to empower global semiconductor manufacturing, supporting "Made in China" to reach new heights.

Follow SBT Ultrasonic to learn more about innovative technologies and collaborate toward a future of precision manufacturing!

Content provided by SBT Ultrasonic. For detailed device parameters and performance, refer to the latest official specifications.